Small laser engravers and handheld engraving tools are becoming essential equipment for creators, small business owners, and DIY makers in 2025. Whether you want to start profitable laser engraver projects or simply enjoy crafting personalized gifts at home, a compact and affordable laser engraver gives you professional results without needing a large workshop.

This guide explains what a small laser engraver is, why it is booming in 2025, which features matter the most, what you can create, and how to choose the right model based on your budget and needs.

What Is a Small Laser Engraver

A small laser engraver is a compact engraving and cutting machine designed for creators who want precision in a lightweight and desk-friendly format. It typically includes a diode, CO2, or IR laser source and can engrave materials such as wood, leather, coated metals, paper, acrylic, and fabric.

Small engravers typically fall into two categories:

Desktop small laser engraver

- Sits on a table or workbench

- Small footprint—easy to place and operate in almost any corner of your home

- Suitable for engraving and light cutting

- Popular among hobbyists, students, craft sellers, and home creators

Handheld laser engraver

Also known as a laser engraver handheld, this is a portable engraving tool that can be lifted and used directly on objects.

- Ideal for creators who engrave items that cannot be placed inside a machine

- Great for on site engraving at markets, events, and workshops

- Works well for metals, leather items, wooden boards, and small products

Both types are designed to be easy to use and accessible to beginners.

Why Small Laser Engravers Are Booming in 2025

Small laser engravers are becoming one of the fastest-growing creative tools in 2025. Several trends are driving this growth:

Growing demand for personalized handmade products

Consumers increasingly prefer custom gifts, name-engraved items, and small batch handcrafted products. This opens opportunities for creators and small shops.

Portable tools are becoming more popular

Hand held laser engravers allow creators to engrave anywhere, such as in a studio, classroom, or craft market. Portability expands where creators can work.

Lower learning barriers

Modern laser engraving tools come with auto focus, beginner friendly interfaces, and intuitive apps. More people can start engraving without prior technical skills.

Affordable pricing

The laser engraving machine price has dropped significantly. Many small and affordable laser engraver models cost far less than large CO2 systems.

Content creator influence

Platforms like TikTok, Instagram, and YouTube have popularized laser engraver projects. Viral engraving videos inspire more people to try the craft.

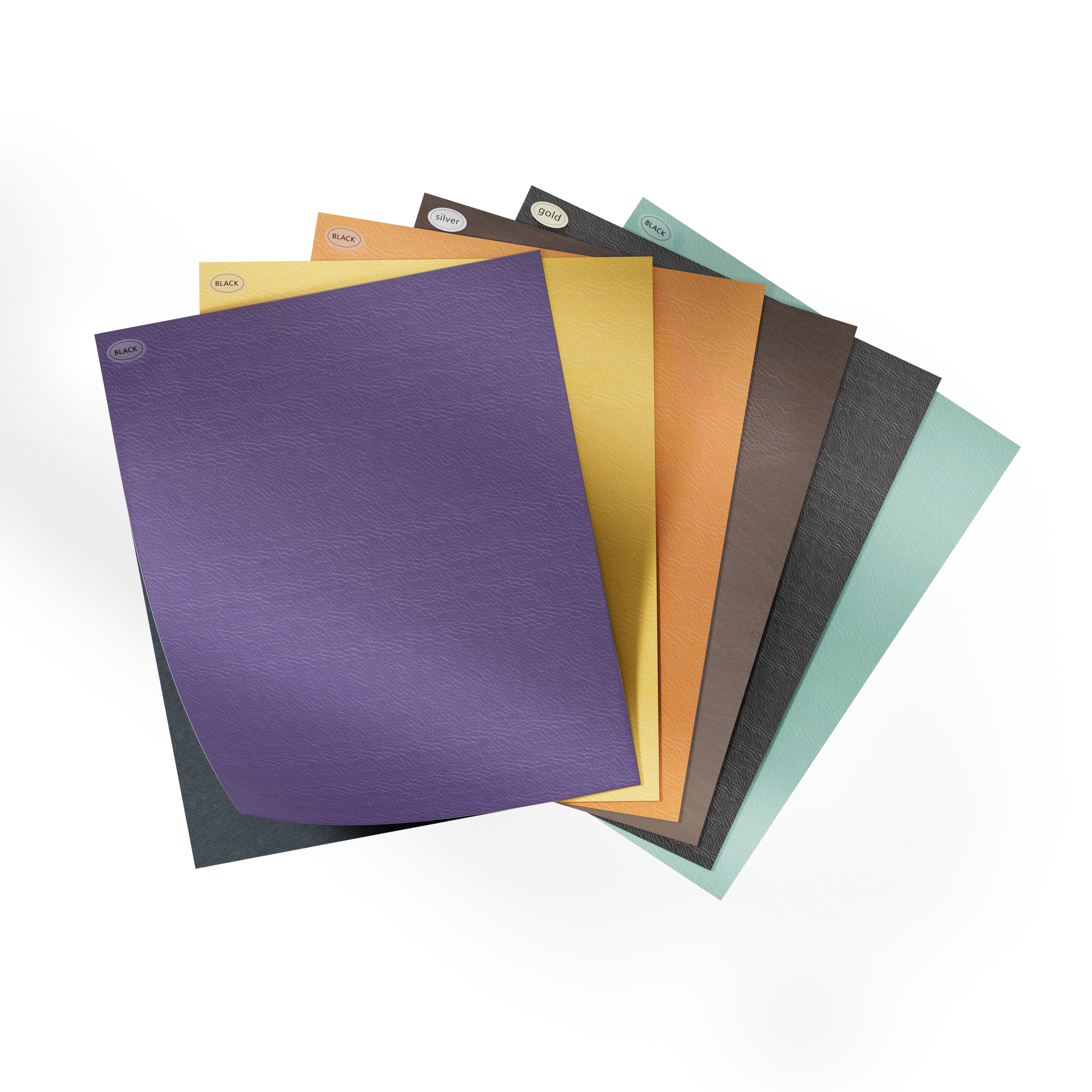

What You Can Make With a Small Laser Engraver

Laser engraver projects are one of the main reasons people buy compact or handheld engraving tools. Here are popular ideas that work with a small laser engraver:

Personalized wooden signs

Leather keychains

Name-engraved notebooks

Jewelry tags

Custom coasters

Cutting board designs

Acrylic ornaments

Gift box engravings

Wedding decor pieces

Small business merchandise

Classroom and student projects

Personalized pet tags

These project ideas work for online shops, local craft markets, and personal gifts.

Types of Small Laser Engravers

Small laser engravers come in several different formats, each designed for a specific type of creator. Choosing the right model depends on your materials, workspace, portability needs, and the type of laser engraver projects you want to make. Below is a detailed breakdown of the most common types, including their best applications, ideal materials, advantages, and limitations.

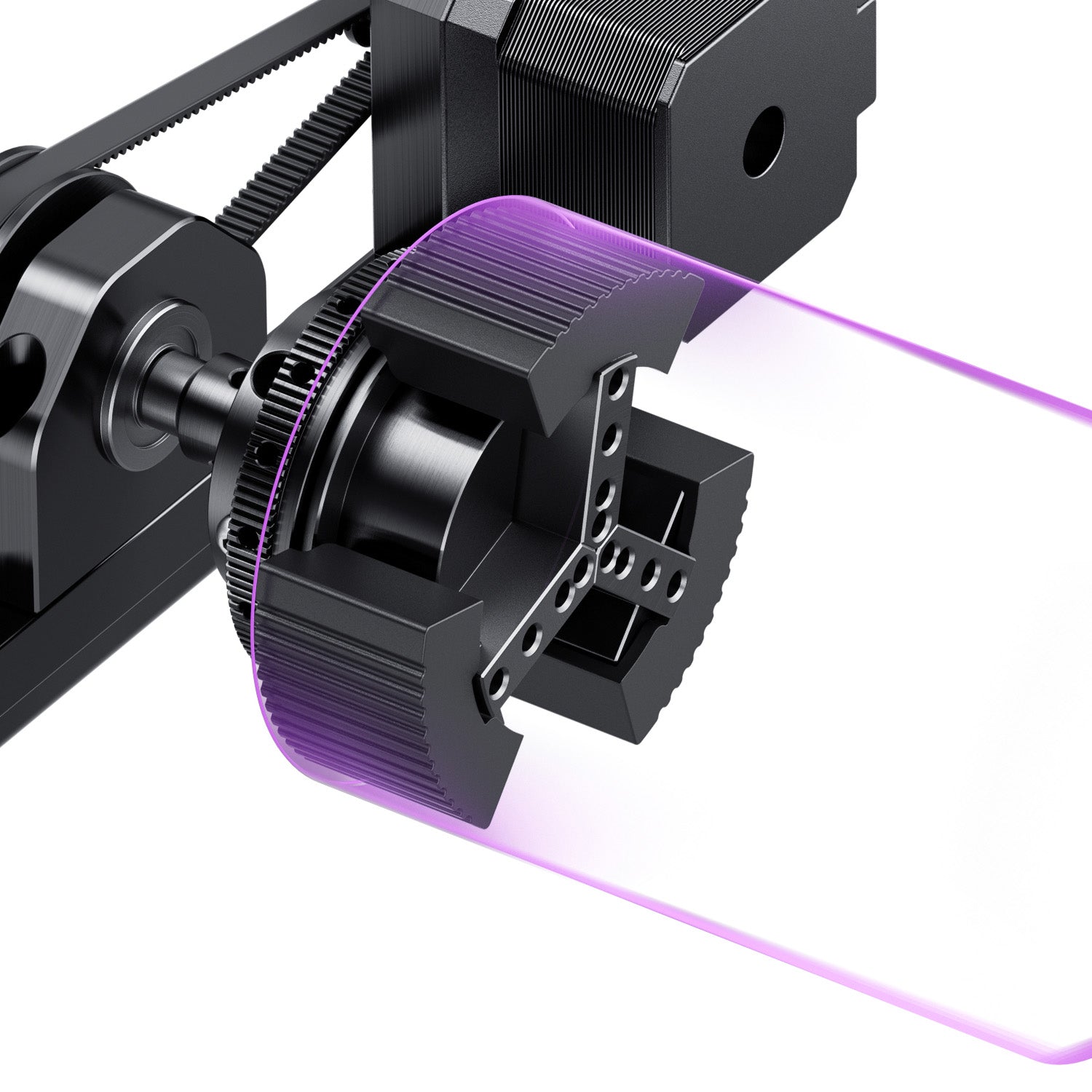

Diode Small Laser Engraver

A diode small laser engraver is one of the most popular options for beginners and home creators. It uses a compact diode laser module that offers solid engraving performance in a lightweight frame.

Best Use Cases: Great for beginners, hobby crafters, and small studios who need a lightweight, portable laser engraving tool for home projects or craft-fair production.

Ideal Materials: Works well on wood, bamboo, leather, coated metals, acrylic, paper, and fabric.

Pros: Affordable, compact, easy to set up, and safe for indoor use thanks to low heat output and diode efficiency.

Cons: Not suitable for engraving bare metals directly and has slower processing speeds compared with CO₂ or fiber systems.

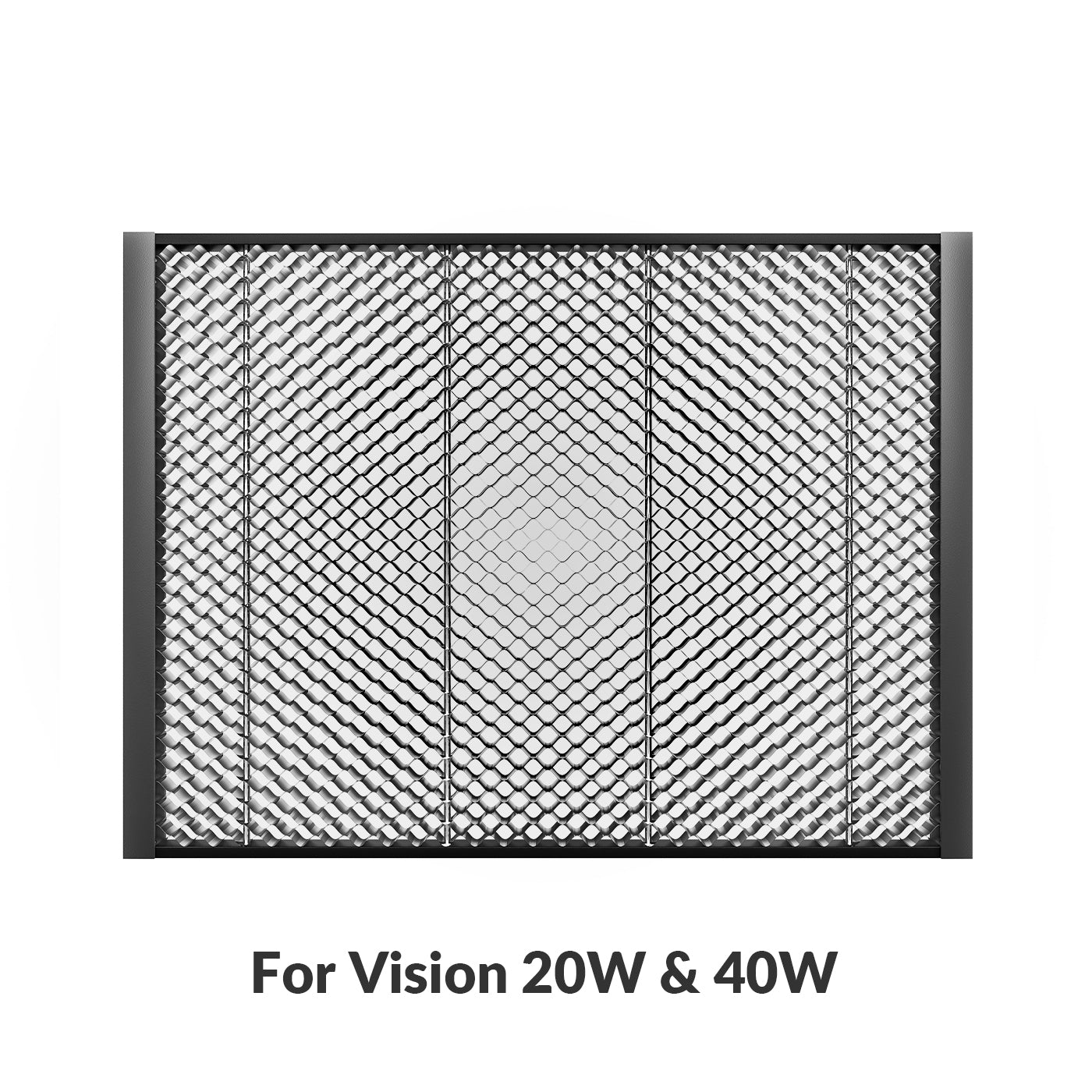

CO₂ Small Laser Engraver

Best Use Cases: Suitable for creators who prioritize high-quality engraving and cutting on non-metal materials, especially for business-level craft production.

Ideal Materials: Excellent for acrylic, wood, leather, rubber stamps, paper, and other organic materials.

Pros: Fast processing speed and exceptional engraving quality, especially on acrylic and soft materials, making it ideal for professional shops.

Cons: Less portable, requires ventilation, and generally has a higher machine price compared to diode options.

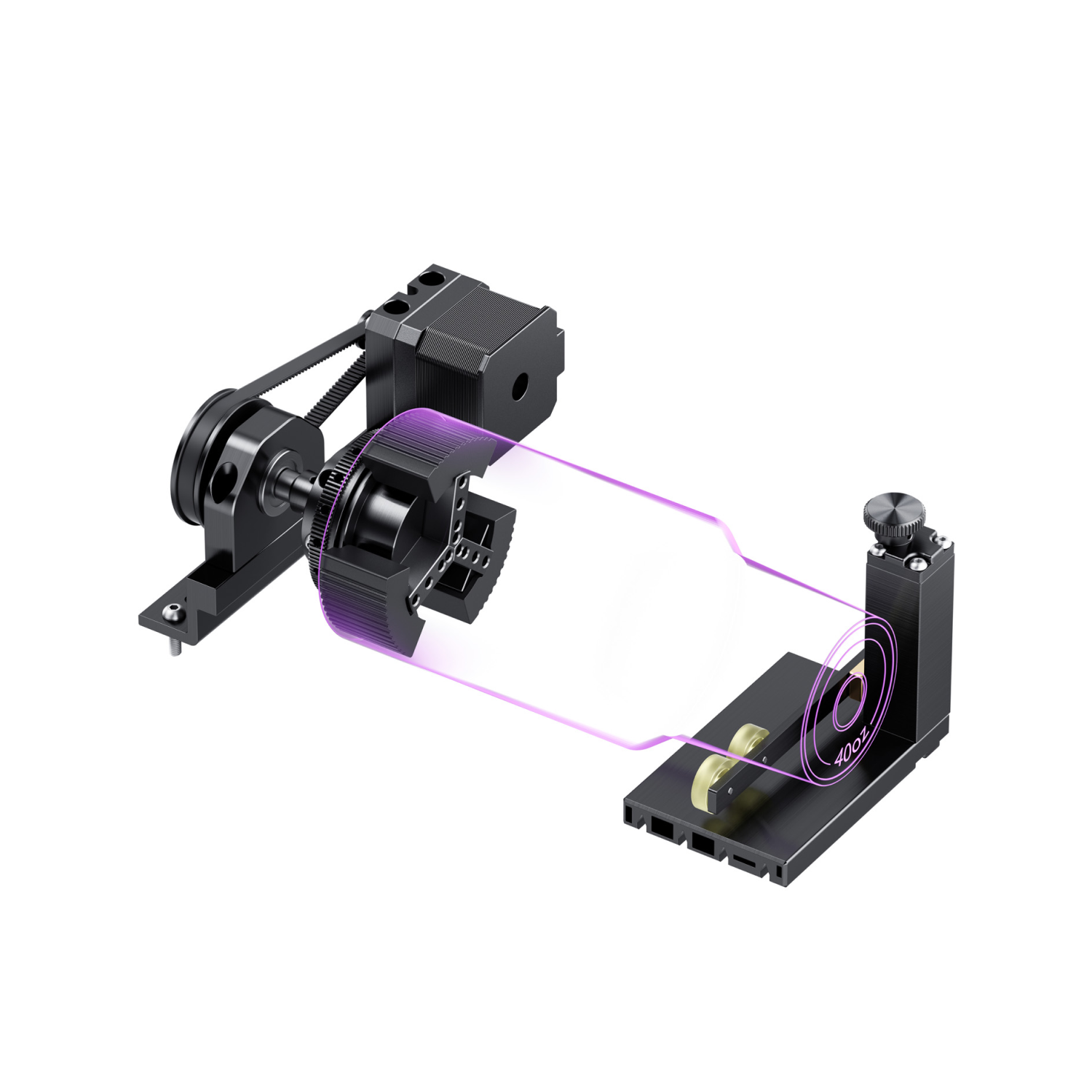

Fiber Laser Handheld Engraver

Best Use Cases: Ideal for users who need to mark bare metals directly—perfect for industrial tags, jewelry personalization, metal craft businesses, and workshop production.

Ideal Materials: Stainless steel, aluminum, titanium, brass, and other bare metal surfaces.

Pros: Delivers clean, permanent markings on metal with high precision and very fast speed.

Cons: Higher upfront price and usually limited to marking (not cutting), making it less versatile for mixed-material creators.

Dual-Laser Engraver

A Dual-Laser Engraver (also called a hybrid laser system or dual-source engraver) typically combines two different laser types in one machine. Each laser excels at engraving different materials, giving the device a much wider working range than a single-laser engraver.

1. Diode + IR (Infrared) Laser

What it includes

- Blue Diode Laser — usually 5W–20W optical power

- 1064nm IR Laser— specialized for metal marking

| Feature | Blue Diode Laser | IR Laser (1064nm) |

|---|---|---|

| Best For | Wood, leather, acrylic, plastics | Metal marking (including bare metals) |

| Beam Wavelength | 455nm | 1064nm |

| Cutting Ability | Good for wood & acrylic | Not for cutting |

| Engraving Detail | Great for organic materials | Ultra-fine metal marking |

| Typical Use | Crafts, gifts, hobby projects | Jewelry, tools, metal tags |

Who uses this combo? Creators who want both craft engraving + metal engraving in one compact machine.

2. Diode + CO₂ Laser

What it includes

- Diode laser for precise engraving

- CO₂ laser (usually 10W–40W tube) for cutting & engraving non-metals

| Feature | Diode | CO₂ |

|---|---|---|

| Best For | Wood, leather, coated metals | Wood, acrylic, rubber, fabric |

| Cutting Power | Moderate | Strong cutting ability |

| Engraving Detail | Precise but shallow | Smooth and deep |

| Footprint | Very compact | Requires ventilation, larger frame |

Who uses this combo? Shops needing fine engraving + strong cutting within one device.

3. CO₂ + Fiber Laser

What it includes

- CO₂ laser for non-metal cutting (wood, acrylic, rubber)

- Fiber laser (20W–50W) for metal engraving

| Feature | CO₂ | Fiber |

|---|---|---|

| Best For | Wood, acrylic, leather | Bare metals, industrial marking |

| Cutting Ability | Excellent for non-metals | Poor (mostly marking) |

| Engraving Speed | Fast | Very fast on metals |

| Machine Size | Medium–large | Medium–large |

Who uses this combo? Professional makers or factories requiring metal + non-metal production in one system.

With the rise of personalized products and demand for multi-material customization, dual-laser engravers are becoming a popular choice for creators who want maximum versatility without expanding their workspace.

Key Features to Look For in a Small Laser Engraver

When choosing an affordable laser engraver or handheld engraving tool, pay attention to these important features:

Part 1: Factors That Determine What Small Laser Engraver You Should Choose

1. Your Budget

Your budget directly determines the type of laser head you can choose and the overall performance you can expect.

$200–$500: Entry-level diode engravers (Beginner Tier)

Entry-level small laser engravers in this range are suitable for hobby use, testing ideas, and light engraving — but they also come with limitations users should be aware of:

- Minimal or no enclosure, meaning more smoke, odor, and exposure to bright laser light; goggles are often required.

- Lower structural stability, which can affect engraving precision, especially on detailed designs.

- Limited cutting ability, usually only thin wood or soft materials.

- Basic safety controls, sometimes missing auto-pause, flame detection, proper shielding, or airflow systems.

-

Shorter lifespan, due to simpler cooling, lighter frames, and cheaper laser modules.

These machines are fine for small DIY projects, learning, or trying laser engraving for the first time — but they are not ideal for long sessions or business use.

$500–$1,000: Mid-range diode or portable dual-laser options

More powerful diode modules become available, plus early dual-laser models (diode + IR).

Expect better safety, faster engraving, and wider material support — suitable for hobby sellers or craft creators.

$1,000+: Premium desktop or hybrid dual-laser systems

These machines offer better precision, stable frames, cameras, auto-focus, larger work areas, and more advanced safety systems.

Great for small business production, detailed engraving, and consistent daily use.

2. Your Purpose: What Do You Want to Do With It?

Your use case will decide which laser type and power level you actually need.

- For hobby crafting: Wood, leather, acrylic, coated metals → diode or dual-laser.

- For metal marking: Need IR laser or fiber-like IR modules.

- For small business personalization: Faster engraving, better precision, larger workspace, possibly handheld flexibility.

- For on-site events, markets, craft fairs: Prioritize portability, quick setup, and handheld mode.

3. Who Should Buy a Small Laser Engraver

Not everyone needs a full-size laser machine. Small models are ideal for:

- Beginners exploring laser crafting as a hobby

- Crafters selling small personalized items

- Exhibitors or market booth sellers needing portable/handheld engraving

- Makers in limited spaces (home studio, apartment, shared workshop)

If your work involves large plywood sheets, heavy-duty cutting, or industrial batch production, a small laser engraver may not be sufficient.

4. Portability Requirements

Decide whether you need:

- Desktop-only (stable, precise, fixed workspace)

- Portable (easy to move between home, school, studio)

- Handheld capability (engraving on curved, large, or mounted objects)

If you frequently attend events, markets, or install engravings directly on products, a portable + handheld model is a major advantage.

Part 2: Technical Features & Functions You Should Look At

| Feature / Parameter | What it means / Why it matters |

|---|---|

| Laser power / Laser type | Output power and wavelength determine engraving and cutting performance. Lower power suits wood and leather engraving; higher power, CO₂, or IR modules enable deeper cutting and metal marking. |

| Work area / Bed size | Defines the maximum material size you can process. Small work areas are ideal for gifts and small crafts; larger ones support batch production and bigger pieces. |

| Auto Focus / QuickView / HD Camera | Auto Focus ensures perfect distance for crisp engraving without manual tuning. QuickView preview systems help you position designs accurately on materials. HD cameras allow real-time framing, precise alignment, and easier multi-item engraving. |

| Engraving / Cutting speed | Affects workflow efficiency. Faster machines allow you to complete more projects per hour, especially important for sellers and small businesses. |

| Laser spot size / Precision / Resolution | Determines detail quality. A smaller spot size produces more accurate lines, sharper text, and clearer photo engraving. |

| Material compatibility | Indicates which materials the machine can engrave: wood, leather, acrylic, coated metal, fabrics, paper, stone, and in some cases bare metal (with IR or fiber modules). |

| Air assist / Exhaust / Ventilation | Removes smoke and debris during engraving. Helps achieve cleaner cuts, reduces odor, and makes indoor use safer. |

| Cooling / Build quality | Good cooling prevents overheating; a rigid frame stabilizes motion for precise, consistent engraving. |

| Software compatibility & connectivity | Check whether the engraver supports LightBurn, mobile apps, and common formats like SVG, DXF, PNG, and JPG. Smooth software workflow improves productivity. |

| Portability / Footprint / Weight | Important for small spaces, shared rooms, or creators who need to use the engraver at markets, workshops, or events. Handheld usability adds extra flexibility. |

| Safety features | Enclosures, interlocks, emergency stop buttons, safety-rated eye protection, and proper exhaust help make the machine safe for home and studio use. |

Conclusion

Small laser engravers and handheld engraving tools give creators a powerful way to make personalized products in a compact and budget friendly format. With lower prices, better software, and improved engraving performance, 2025 is one of the best times to start exploring laser engraver projects.

Whether you want an affordable laser engraver for home crafting or a portable hand held laser engraver for small business work, compact machines now offer professional results that fit comfortably on your desk or in your hand.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.